It’s a snowy day at the farm. Winter seems to want to linger a few more weeks. In between stoking the wood stove and working on my latest loom project, I thought I’d continue to weave my weaving tale (sorry).

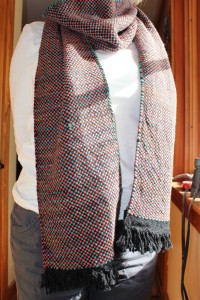

In Weave Dreamer – I, I started by writing I was on my 4th project since moving to the farm, but didn’t show any of my more recent work. I don’t remember the exact order, but I think the first scarf (and most of my projects are scarves) used yarn that Peg and I picked out at the Maryland Sheep and Wool Festival in May, 2012. Using black yarn for the warp, and alternating red and green/blue yarn for the weft, I produced this piece. The width is nice at about 8.5 inches, but I got a little carried away on the length – over 7 feet.

If you’re interested in this one, I’ve set up an Etsy shop, and this is the only item currently in the shop.

My next project proved to be very frustrating, and it sat on the loom for a couple months. Last fall, I purchased a couple skeins of yarn at the Green Mountain Fiber Festival just down the road in Wilder. One was white Navajo-Churro yarn which the vendor said was great for warp. So I put that on the loom, alternating it with some gorgeous merino/cashmere/silk yarn that I also got in Maryland. For the weft, I also used the blend. The pattern they made was really wonderful.

Unfortunately, after about six inches of weaving, the white yarn began to come apart. I tried to keep it going for about another foot, but more white kept breaking. That project sat on the loom from Thanksgiving until the end of January. I found a website for the vendor and sent her a note expressing my frustration – no reply.

Peg told me to scrap it and start another project. I really didn’t want to waste that gorgeous blend yarn – its colors go from green to brown to rust to purple. I thought there might be some way to save the mix on the loom but get rid of the remaining white.

The last week in January, Peg travelled to Miami (nice timing). While she was gone, I attacked the failed project. I cut off the “completed” 18 inches that had been sitting for months, reset the loom with only the colorful mix, and proceeded again. In only about two days, I had a pretty neat little scarf that measures about 4.5 feet long and 3.5 inches wide. It’s short because of the 18 inches I lost on the first project, and it’s narrow because half of the warp (the white yarn) was sitting on the floor.

I tried desperately maximize the length on the project. At the very end, to keep tension on the warp, I tied the ends to a 20 pound dumbbell sitting on the floor behind the loom – just to try to squeeze out a few more inches.

Peg’s birthday was the next week. What a great surprise this would be. Before she returned from Miami, I had finished and hidden the little scarf, and set up another project on the loom. I put the scarf in a box alongside a can of Trader Joe’s Wintry Blend (which she loves) and it was a real hit.

I’m now about 15 months into weaving, and I’m getting more confident in my abilities. There is so much more to learn (and I’ll need to find a teacher or classes), but projects aren’t nearly as daunting as they once were. The first few times I measured out the warp, I actually had difficulty keep track of how many loops of yarn I had put on the frame. For a six foot long scarf, a loop of yarn is about 16 feet long (2 x 6 feet for the scarf, and 4 feet waste at the beginning and end). For an eight inch wide scarf, that’s about 46 loops. Not 45, not 47. Now I find it easier to concentrate, and I can measure out a warp in about 15-20 minutes.

After measuring out the warp, it needs to get put on the loom – probably the most challenging part of weaving for me. It’s easy to just put the loops of yarn on the front and back beams of the loom. It’s not so easy when you have to make sure there are no tangles or crosses of the threads, and space them evenly on the beam. One early project I tried with some cotton yarn that came with the loom got so mixed up, I scrapped the whole mess rather than try to figure out a solution. Now I actually enjoy this part of the process, and get more efficient and more effective each time. By effective, I mean putting the warp on the beams evenly so that each thread is the same length and has the same tension.

Next installment – probably a few more scarves.

Todd

- Available on Etsy

- Happy Birthday Peg

- Dumbbell for Tension

- Failed Project

- Pattern Before Disaster